AUTOMATED VERTICAL WAREHOUSES

AUTOMATED VERTICAL WAREHOUSE: WHAT IS IT?

The automated vertical warehouses use mechanical structures moving between two rows of racks to carry out the load AS/RS (storage / retrieval) operations.

The stored containers are trays whose features and dimensions are determined by specific characteristics of the goods.

The whole structure is fully enclosed by walls and therefore isolated from the company surrounding environment; the only openings are one or more “bays” through which the trays are set available by the system.

The handling operations are controlled by software through the appropriate station placed next to the bay.

ADVANTAGES:

SPACE – SAFETY – EFFICIENCY – SAVINGS

- Up to 80% space saving in relation to the traditional racks

- Reduction of the inefficiencies and reduction of the employed resources

- Better ratio between occupied floor and storage capacities (in terms of weight and volume)

- Zeroing of the injury risks and consequently of the related costs

- Material care and computer control of all the moved quantities

- Quick pay-back of the investment (2 to 3 years)

- High degree of company progressive development and company technological image

- Tray sizes length from 1200mm to 2400mm and depth from 800mm to 1000mm. Max payload 500 kg.

THE WAREHOUSE WHICH DOES NOT (PRE)OCCUPY BUT SOLVES

THE SOLUTION TO QUICKLY AND SAFELY MANAGE THE WAREHOUSE ACTIVITIES.

UNO is the warehouse that makes the goods picking/storage activity rapid and economic.

The high-rise of this automatic system permits to clear spaces and free efficiencies so as to improve the whole company productivity.

THE VERSATILE WAREHOUSE

WIDE RANGE, FOR AN EFFICIENT STORAGE CAPACITY

SPAZIO represents the automated vertical warehouse range which, thanks to their modular structure can be “made to order” for every company.

Namely from 2 to 7 modules to have the most suitable warehouse solution to employ the spaces at the best for a proper storage capacity and a higher logistic efficiency.

THE UNLIMITED WAREHOUSE

HIGH FLEXIBILITY DEGREE FOR HIGH SPACE AND STORAGE REQUIREMENTS

UNICO is the most progressive model in the automated vertical warehouses. Thanks to the Stacker-Crane structure carrying out the automatic operations inside the machine, UNICO can be upgraded both lengthwise and in height guaranteeing a comprehensive response to any necessity of quantities to be stored.

ACCESSORIES

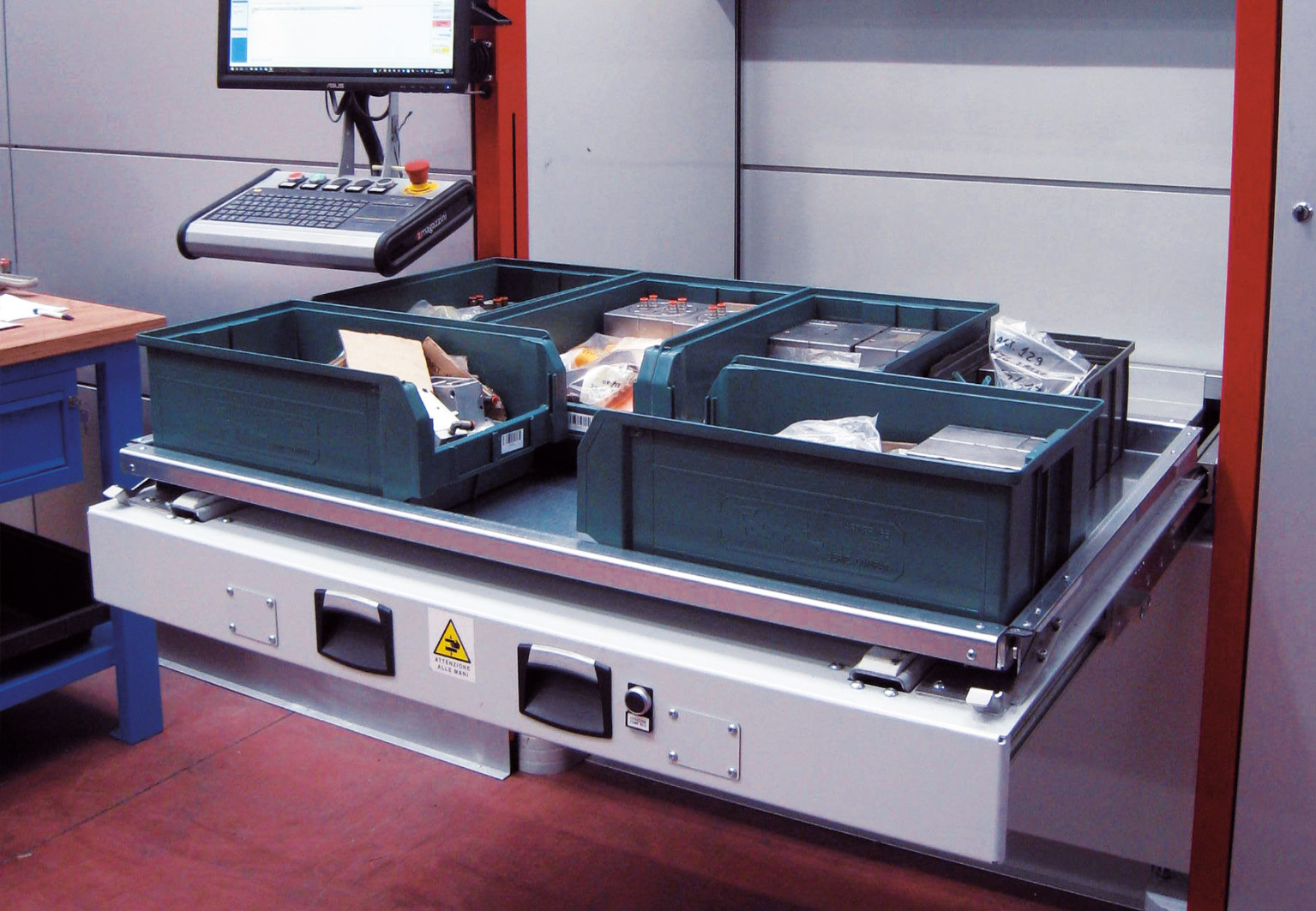

TRAYS

Trays are the Load Unit for the goods storage; they are provided with sliding blades allowing for their storage/retrieval. They are available in various dimensions and

payloads.

PERIMETRY EDGES

The trays may be provided with perimetry edges of various heights suitable for creating an internal subdivision by means of suitable partitions.

LED BAR

It is a visual detection operating by LEDs and showing the goods pickup/deposit zone inside the tray.

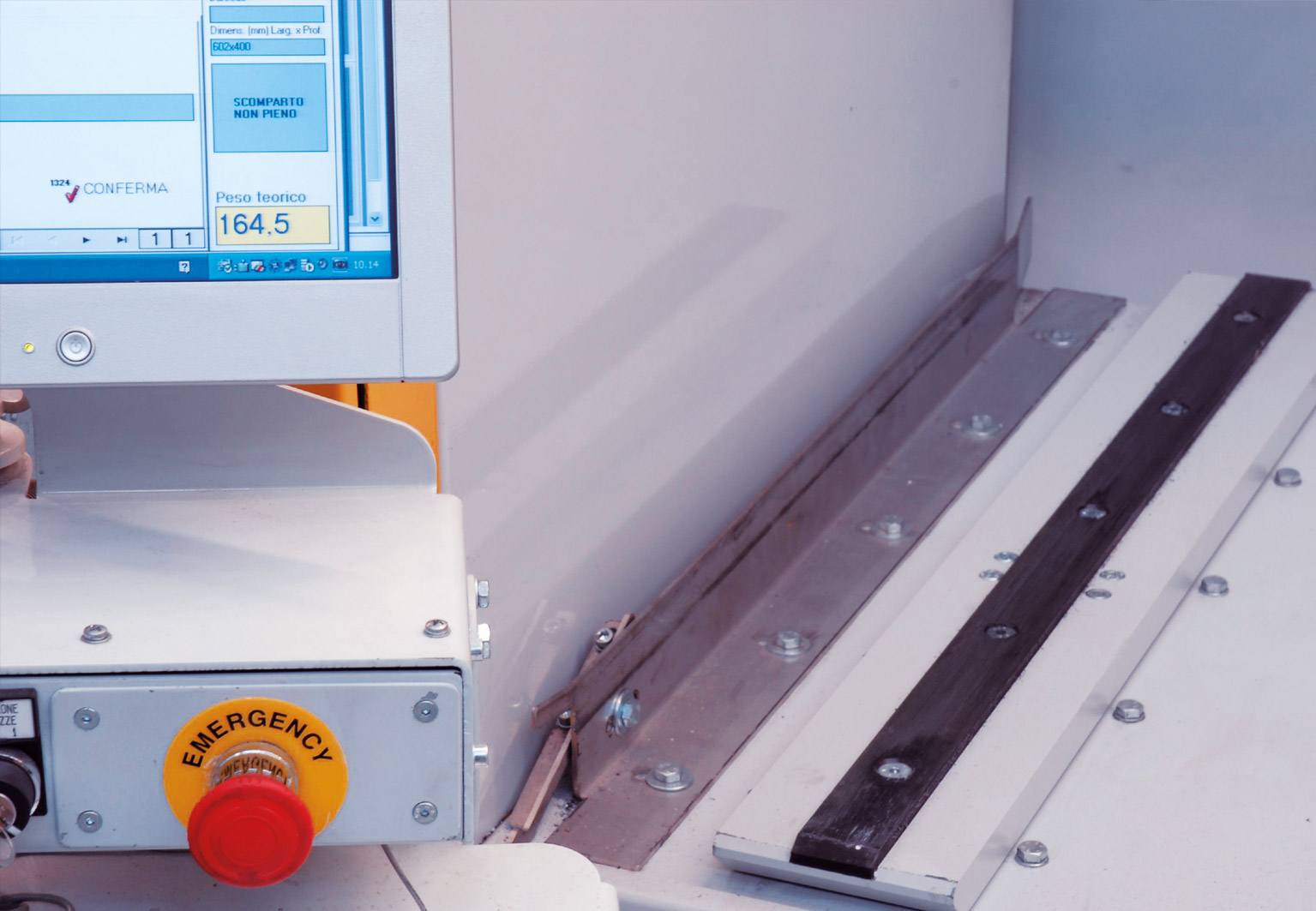

WEIGHT CHECK

The load cells permit to check the weight inside the tray thus avoiding to store an overload with respect to the maximum payload.

MANUAL EXTRACTION OF THE BAY PLANE

This solution helps the operator in extracting (on suitable telescopic guides) the tray which is normally inside the bay. In such a way, the operator will be able to lift possible heavy goods with the help of “zero gravity” load handling apparatus. Once the operation is finished, the bay plane can be reinserted in its original position which means no fixed external obstacles.

EXTERNAL BAY PLANE

The solution enables the operator to lift possible heavy goods with the help of “zero gravity” load handling apparatus. The bay plane is external and fixed.

TROLLEY FOR THE TRAY MANUAL EXTRACTION

The trolley allows to completely extract the tray and move it elsewhere (ex. Assembly areas).

ZERO GRAVITY MANIPULATOR

The manipulator is fixed directly to the machine structure (max. lifting capacity 125 kg.). This solution avoids having obstacles on the floor.

ORDER PREPARATION TABLE

The table gives the possibility to work on several pickup lists simultaneously allowing for a massive pickup. It is made of a fix metal frame equipped with “n” stations each one identified with one or more alphanumeric lighting LCDs. The whole system is controlled by the machine software.

DOUBLE BAY

This solution may be implemented to the SPAZIO and UNICO models. There will always be a tray present at one of the two bays which eliminates the downtimes. The position of the trays, always at the same height, guarantees an ergonomic operation.