https://zecchetti.it/wp-content/uploads/2018/03/disegno_tecnico.jpg

1402

1784

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:562018-11-25 12:11:40Integrating Production, Retrieval And Storage

https://zecchetti.it/wp-content/uploads/2018/03/disegno_tecnico.jpg

1402

1784

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:562018-11-25 12:11:40Integrating Production, Retrieval And StorageHIGHLIGHTS

https://zecchetti.it/wp-content/uploads/2018/03/disegno_tecnico.jpg

1402

1784

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:562018-11-25 12:11:40Integrating Production, Retrieval And Storage

https://zecchetti.it/wp-content/uploads/2018/03/disegno_tecnico.jpg

1402

1784

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:562018-11-25 12:11:40Integrating Production, Retrieval And Storage https://zecchetti.it/wp-content/uploads/2018/03/pallet2.jpg

671

758

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:022018-11-25 12:12:57Automatic Change - Over? A matter of skill

https://zecchetti.it/wp-content/uploads/2018/03/pallet2.jpg

671

758

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-20 11:17:022018-11-25 12:12:57Automatic Change - Over? A matter of skill https://zecchetti.it/wp-content/uploads/2018/03/FTL_7504.jpg

2398

3603

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-12 11:47:512018-11-25 12:13:52Two distant cultures come together and cooperate for mutual success

https://zecchetti.it/wp-content/uploads/2018/03/FTL_7504.jpg

2398

3603

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-12 11:47:512018-11-25 12:13:52Two distant cultures come together and cooperate for mutual success https://zecchetti.it/wp-content/uploads/2018/03/01.jpg

752

1200

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

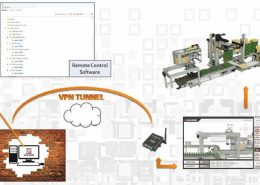

alessandro2018-03-12 10:18:352018-11-25 12:15:01Zecchetti total support with advanced tools - ensuring their uninterrupted operation

https://zecchetti.it/wp-content/uploads/2018/03/01.jpg

752

1200

alessandro

https://zecchetti.it/wp-content/uploads/2020/10/logo-zecchetti-ems.png

alessandro2018-03-12 10:18:352018-11-25 12:15:01Zecchetti total support with advanced tools - ensuring their uninterrupted operationABOUT US

Zecchetti srl

Via Galileo Galilei, 1 – 1/A

42027 – Montecchio Emilia (RE) – Italy

Phone +39. 0522.867411

Fax. +39. 0522.866034

info@zecchetti.it

Via Galileo Galilei, 1 – 1/A

42027 – Montecchio Emilia (RE) – Italy

Phone +39. 0522.867411

Fax. +39. 0522.866034

info@zecchetti.it